Landscape transformation services help cement LafargeHolcim merger

"Through hard work, professionalism and lots of team effort, we carved out the divested business".

The EPI-USE Labs team rose to the challenge and leveraged offshore resources to ensure development continued around the clock!

Kathy McLeod, LafargeHolcim’s Head of Applications and Design

In brief: A successful merger

In 2014, Holcim and Lafarge, two independent companies in the building materials industry, announced a merger. With a combined market value exceeding $50 billion, their merger was the second largest announced in 2014 worldwide. Since a merger of this scale would raise regulatory concerns, Holcim decided to divest part of its business, accounting for 10 to 15% of the company’s EBITDA.

For this complex and large-scale divestiture project, Holcim contacted EPI-USE Labs. In the course of only three months and one week, Holcim and EPI-USE Labs successfully divested the Canadian business, along with selected US terminals and a US plant into a completely isolated environment. This was achieved with no production system downtime, by leveraging Holcim’s Disaster Recovery infrastructure.

Despite significant changes during the project, EPI-USE Labs easily re-configured its products to adjust to the new requirements. Close collaboration between EPI-USE Labs and Holcim’s functional specialists ensured that the requirements were feasible and modelled correctly.

By successfully achieving the divestment deadline, Holcim could proceed with the merger with Lafarge.

The full LafargeHolcim success story

The challenge

In April 2014, Holcim and Lafarge, two independent companies, announced a merger. With a combined market value exceeding $50 billion, their merger was the second largest announced in 2014 worldwide. Since a merger of this scale would raise regulatory concerns, Holcim decided to divest part of its business. The divestments accounted for 10 to 15% of the company’s EBITDA.

There were several forces at play throughout:

- Dependency of the LafargeHolcim merger on the successful completion of the divestment project

- On-going negotiations with the buyer of the divested business during the project

- Strict regulatory requirements for system and data isolation

- Highly aggressive timelines with a fixed end-date

Further complications arose in mid-project when regulatory and commercial requirements forced significant changes to the scope.

We had a good relationship with EPI-USE Labs and reached out to them to understand how they could assist with this endeavor. They thoroughly explained the process and connected us with other customers who shared their experiences.

Kathy McLeod, LafargeHolcim’s Head of Applications and Design

The solution

For this complex and large-scale divestiture project, Holcim contacted EPI-USE Labs. Holcim was already a customer of EPI-USE Labs, using their Data Sync Manager™ (DSM) products to effectively manage and optimize their SAP® landscape.

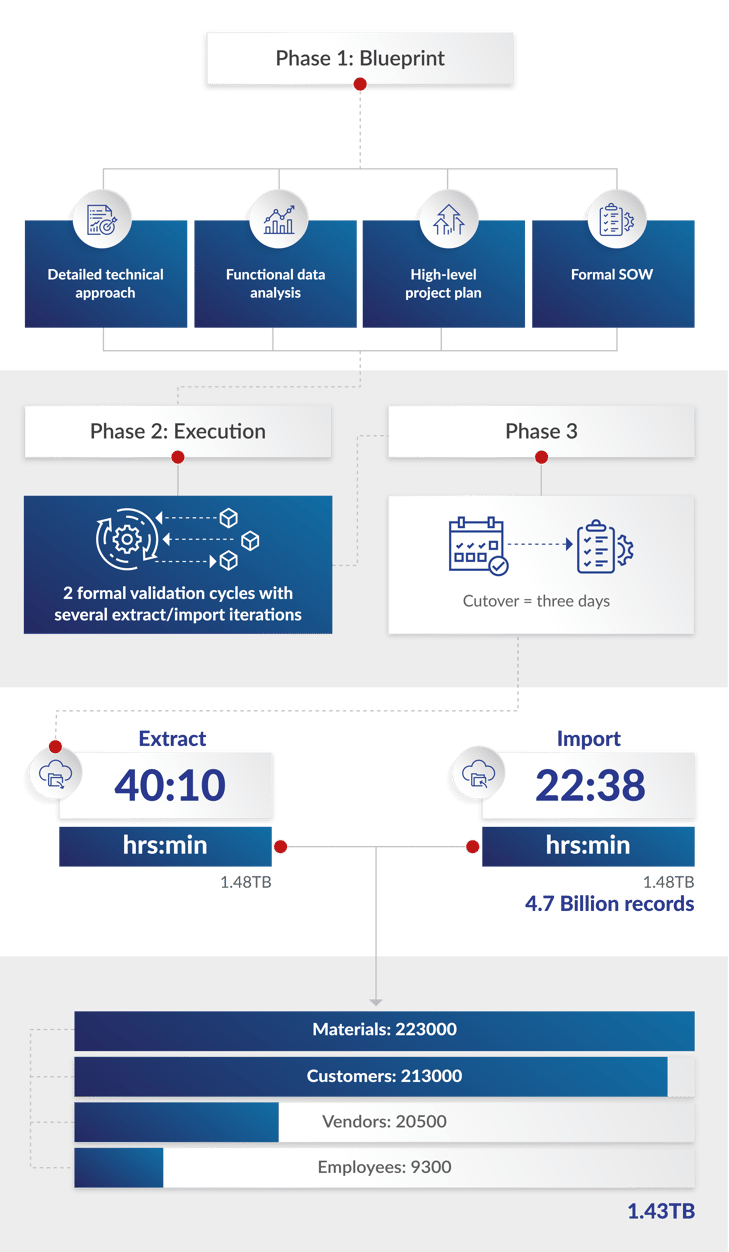

EPI-USE Labs kicked off with a detailed Blueprinting workshop involving Holcim’s technical and functional teams, conducted over two weeks in March 2015. The Blueprint included a high-level schedule, landscape architecture, and functional data analysis, plus a formal SOW (Statement of Work) that defined deliverables, roles and responsibilities.

This careful preparation for execution of the divestiture gave Holcim’s management confidence in the project, and they decided to move ahead. In April 2015, EPI-USE Labs began to install and configure their products, working with Holcim’s Basis team to build the required systems. At the same time EPI-USE Labs worked closely with the functional leads to refine the functional data requirements.

The initial scope of the project included the full divestment of twelve Canadian company codes, including all relevant master and transactional data. Using Data Sync Manager (DSM), they could carve out at the company code level and include all data. Also in the scope was an asset sale of five terminals and one plant, including master data only. Because this sale represented only a portion of the US company codes, it was more challenging: the teams had to identify specific sub-sets of company code data, and needed to adjust for the Financial and Controlling data.

However, at the end of April, regulatory requirements changed, leading to a request to include transactional data related to the terminals and plant.

“The EPI-USE Labs team worked closely with our design team to define and configure the additional rules with as little delay as possible to the schedule,” said Kathy McLeod.

In May, the first validation cycle took place, with Holcim taking the lead and EPI-USE Labs adjusting the initial carve-out model. In the final days before cutover in June, additional requirements surfaced: to include two additional Canadian company codes and two virtual plants, and load the delta payroll run for hourly employees. As business testing was nearly complete, this introduced a large risk to the entire project. “The EPI-USE Labs team rose to the challenge and leveraged offshore resources to ensure development continued around the clock,” said Kathy McLeod.

The outcome

In the course of only three months and one week, Holcim and EPI-USE Labs successfully divested the Canadian business, along with selected US terminals and a US plant into a completely isolated environment. This was achieved with no production system downtime, by leveraging Holcim’s Disaster Recovery infrastructure.

Despite significant changes during the project, EPI-USE Labs easily re-configured its products to adjust to the new requirements. Close collaboration between EPI-USE Labs and Holcim’s functional specialists ensured that the requirements were feasible and modeled correctly.

Ultimately, Holcim was able to use the new landscape to seamlessly execute the TSA (Transitional Services Agreement) signed with the buying entity. By successfully achieving the divestment deadline, Holcim could proceed with the merger with Lafarge.

The post- cutover support provided by EPI-USE Labs was key to ensuring any minor issues were resolved in a timely manner.

The EPI-USE Labs team worked closely with our Project team to understand the requirements, propose options, offer guidance and highlight the risks. All parties understood it was a very aggressive timeline and we mitigated the risk by having multiple on-site workshops to ensure a common understanding of all key decisions. I was certainly in daily communication as we navigated through the critical phases.

Kathy McLeod, LafargeHolcim’s Head of Applications and Design

Industry: Engineering, Construction and Operations

Solution: PRISM Transformation, Data Sync Manager (DSM)

About Lafarge Holcim

LafargeHolcim is the leading global construction materials and solutions company serving masons, builders, architects and engineers all over the world. With a presence in 80 countries, the most innovative cement, concrete, and aggregates solutions to meet their customers’ needs, and a commitment to health, safety, and sustainability, LafargeHolcim has the assets necessary to address today's global challenges.

- Founded in 2015 following the merger of Lafarge and Holcim

- Presence in 70 countries

- 65, 000 employees

- CHF 26.9 billion in net sales

- 3 mt of installed capacity worldwide

- 2,300 plants (including over 1,400 in ready mix concrete, over 600 in aggregates and over 200 in cement and grinding plants)

- Solutions and services: cement, concrete, and aggregate solutions for the following businesses: buildings, infrastructure, distribution, oil and gas, affordable housing and construction systems

Learn more about how we helped LafargeHolcim

Download PDFRead how other companies succeeded with EPI-USE Labs

Similar stories you might want to read:

Borealis carves out company codes with Data Sync Manager

EPI-USE Labs performs successful company carve-out using Data Sync Manager for Landscape Transformation (DSM LT) for che...

P&O Reyser successfully separates its SAP system from the Berge Group in only three months

"Working with IECISA (now INETUM), and EPI-USE Labs was a very good experience. They were 100% engaged with us, they rea...

Dunelm realigns its SAP non-production system landscape

"Data Sync Manager is very good at taking selective pieces of data that we need, and slicing that into different sizes."